Disc brake is a type of brake that uses the calipers to squeeze pairs of pads against a disc or a "rotor" to create friction . This action slows the rotation of a shaft, such as a vehicle axle, either to reduce its rotational speed or to hold it stationary. The energy of motion is converted into waste heat which must be dispersed.

Hydraulically actuated disc brakes are the most commonly used form of brake for motor vehicles, but the principles of a disc brake are applicable to almost any rotating shaft. The components include the disc, master cylinder, caliper (which contains cylinder and two brake pads) on both sides of the disc.

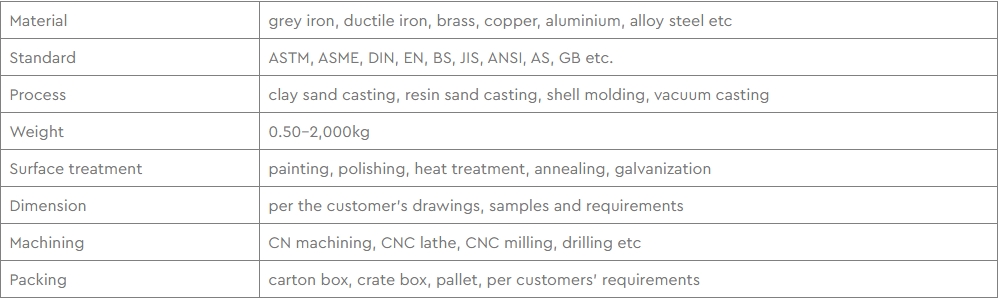

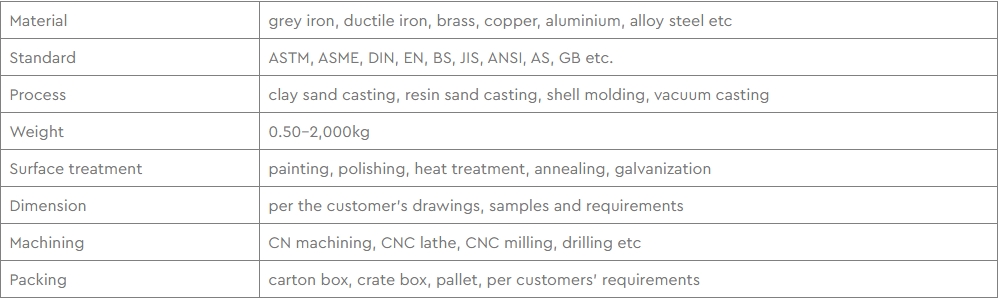

Hengchang is the leading producer of gray, ductile iron in China, melting more than 6000 tons per year, with more than 15 years experience.We produce custom grey iron disc brakes by Resin Sand Casting.In the resin sand casting process, resin and sand are first mixed together. Following that, the mixture is self-hardened through chemical reaction to produce exceptionally hard molds.

- Resin sand casting typically produces accurate results that are superior to other sand-casting methods.

- This process also results in increased surface strength when compared to other sand-casting options

- The nature of resin sand casting can help reduce defects such as sand holes, air holes, and shrinkage.

- More flexibility with sizing

- Resin sand casting can produce large iron castings. These castings can range from dozens of kilograms up to several tons.

-

| Production Line Capabilities |

1.Vacuum Casting Line: Enables large-batch production and smooth surface medium parts

2.Resin Sand Casting Line: Delivers big complex geometries, but small quantity

3.Clay Sand Casting Line: Enables large-batch production small part and smooth surface medium parts

4.Medium-frequency Induction Furnace: Make sure uniform melting and stable quality

Quality is the soul of our foundry, we are equipped with a complete metallurgical laboratory to determine the chemical and mechanical characteristics of each melt and to analyse the metallurgic condition of the molten metal before pouring. Microsections are examined under the microscope to obtain final information.we issue related reports for each delivery part on customers' demand.

IPv6 network supported

IPv6 network supported