A pump housing, also known as a pump casting or body, is the enclosure that surrounds and protects the internal components of a pump. It's a critical part, especially where the pump is exposed to the elements or needs to withstand specific pressures and environments. Among materials, cast iron pump housing is pretty preferable due to its excellent advantages. It is widely used in home appliance equipment,Auto parts,Industrial equipment etc

Hengchang is the leading producer of gray, ductile iron products in China, melting more than 6000 tons per year, with more than 15 years experience. Hengchang is a OEM grey iron pump manufacturer. Cast iron pumps are produced by sand casting, which also known as sand molded casting, is a metal casting process characterized by using sand as the mold material. The term "sand casting" can also refer to an object produced via the sand casting process. Sand castings are produced in specialized factories called foundries . Over 60% of all metal castings are produced via sand casting process.

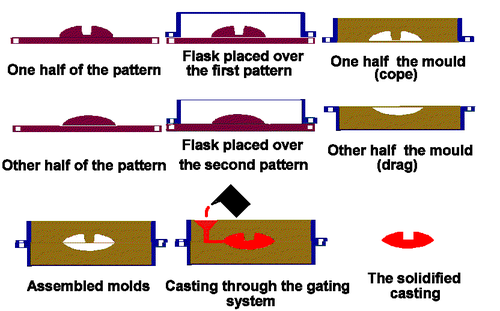

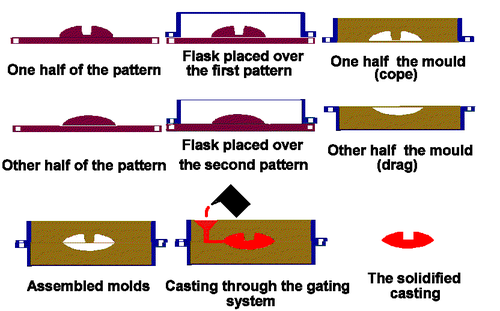

Molds made of sand are relatively cheap, and sufficiently refractory even for steel foundry use. In addition to the sand, a suitable bonding agent (usually clay) is mixed or occurs with the sand. The mixture is moistened, typically with water, but sometimes with other substances, to develop the strength and plasticity of the clay and to make the aggregate suitable for molding. The sand is typically contained in a system of frames or mold boxes known as a flask. The mold cavities and gate system are created by compacting the sand around models called patterns, by carving directly into the sand, or by 3D printing. Here is a simple draft for reference.

| Production Line Capabilities |

1.Vacuum Casting Line: Enables large-batch production and smooth surface medium parts

2.Resin Sand Casting Line: Delivers big complex geometries, but small quantity

3.Clay Sand Casting Line: Enables large-batch production small part and smooth surface medium parts

4.Medium-frequency Induction Furnace: Make sure uniform melting and stable quality

| Material |

grey iron, ductile iron, brass, copper, aluminium, alloy steel etc |

| Standard |

ASTM, ASME, DIN, EN, BS, JIS, ANSI, AS, GB etc. |

| Process |

clay sand casting, resin sand casting, shell molding, vacuum casting |

| Weight |

0.50-2,000kg |

| Surface treatment |

painting, polishing, heat treatment, annealing, galvanization |

| Dimension |

per the customer's drawings, samples and requirements |

| Machining |

CN machining, CNC lathe, CNC milling, drilling etc |

| Packing |

carton box, crate box, pallet, per customers' requirements |

IPv6 network supported

IPv6 network supported