A piston is a component of reciprocating engines, reciprocating pumps, gas compressors, hydraulis cylinders and pneumatic cylinders and pneumatic cylinders,among other similar mechanisms. It is the moving component that is contained by a cylinder and is made gas-tight by piston rings. In an engine, its purpose is to transfer force from expanding gas in the cylinder to the crankshaft via a piston rod and/or connecting rod. In a pump, the function is reversed and force is transferred from the crankshaft to the piston for the purpose of compressing or ejecting the fluid in the cylinder. In some engines, the piston also acts as a valve by covering and uncovering ports in the cylinder

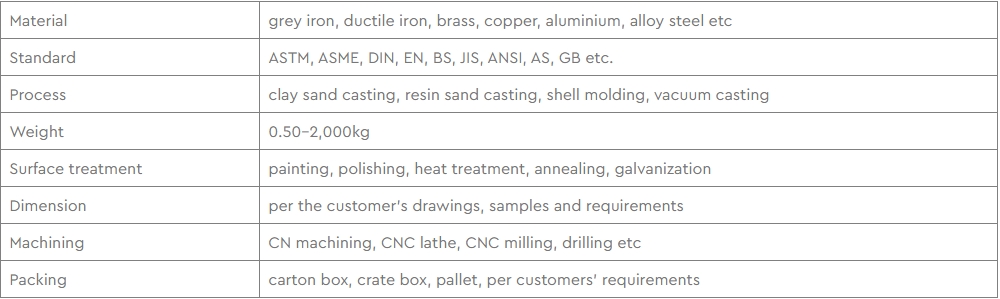

| Production Line Capabilities |

1.Vacuum Casting Line: Enables large-batch production and smooth surface medium parts

2.Resin Sand Casting Line: Delivers big complex geometries, but small quantity

3.Clay Sand Casting Line: Enables large-batch production small part and smooth surface medium parts

4.Medium-frequency Induction Furnace: Make sure uniform melting and stable quality

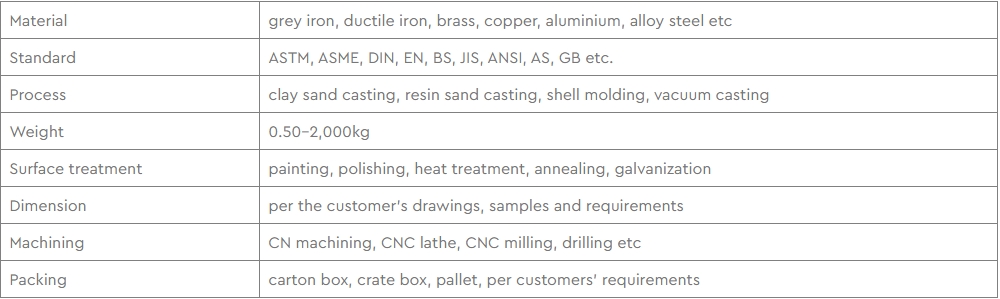

Comparative qualities of cast irons

| Name |

Nominal composition [% by weight] |

Form and condition |

Yield strength [ksi (0.2% offset)] |

Tensile strength [ksi] |

Elongation [%] |

Hardness [Brinell scale] |

Uses |

| Grey cast iron (ASTM A48) |

C 3.4, Si 1.8, Mn 0.5 |

Cast |

— |

50 |

0.5 |

260 |

Engine cylinder blocks, flywheels, gear box cases, machine-tool bases |

| White cast iron |

C 3.4, Si 0.7, Mn 0.6 |

Cast (as cast) |

— |

25 |

0 |

450 |

Bearing surfaces |

| Malleable iron (ASTM A47) |

C 2.5, Si 1.0, Mn 0.55 |

Cast (annealed) |

33 |

52 |

12 |

130 |

Axle bearings, track wheels, automotive crankshafts |

| Ductile or nodular iron |

C 3.4, P 0.1, Mn 0.4, Ni 1.0, Mg 0.06 |

Cast |

53 |

70 |

18 |

170 |

Gears, camshafts, crankshafts |

| Ductile or nodular iron (ASTM A339) |

— |

Cast (quench tempered) |

108 |

135 |

5 |

310 |

— |

| Ni-hard type 2 |

C 2.7, Si 0.6, Mn 0.5, Ni 4.5, Cr 2.0 |

Sand-cast |

— |

55 |

— |

550 |

High strength applications |

| Ni-resist type 2 |

C 3.0, Si 2.0, Mn 1.0, Ni 20.0, Cr 2.5 |

Cast |

— |

27 |

2 |

140 |

Resistance to heat and corrosion |

IPv6 network supported

IPv6 network supported