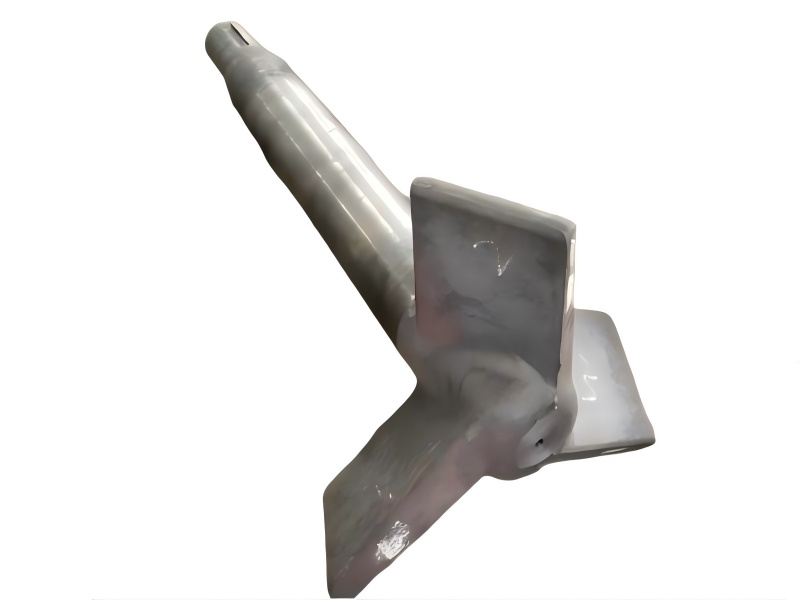

OEM Rolling Mill Guides is most used in the rebars & wires rolling workshops. Custom Rolling Mill Guides treats the billets which is rolled that features different attributes and attractive design. It assures simple installation, safe operation, long-lasting durability, and others

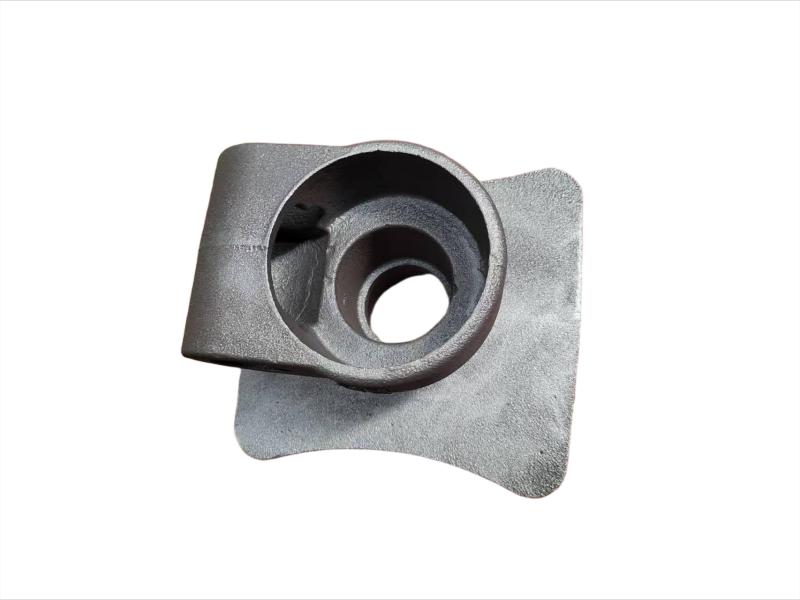

Zhangzhou Hengchang is ductile iron rolling mill guides manufacturer, and use resin sand to produce rolling mill guides. Resin sand is a type of quartz sand that is mixed with a resin material. The chemical reaction created by the resin helps to bind and stiffen the quartz sand to make solid, hard and strong molds. 。 The resin sand can be used to create just a part of the mold, or the entire mold material. The mold can create 3D products in a variety of shapes, configurations and sizes. Once the mold is made, materials are poured into the mold as the sand’s refractory properties help the mold remain stable. Then the sand is removed through a shakeout process as the metal is then cut, ground, finished and assembled into the final product.

A wide variety of metals can be used in resin sand cast molding due to the sand's tolerances to high temperatures. So iron, titanium and nickel alloys can be used in this process.

Advantages of Sand Casting Process:

• Low Cost due to its cheap and recyclable mold materials and simple production equipment.

• Wide range of unit weight from 0.50 kg to 2000 kgs or even bigger.

• Various Structure from simple type to complex type.

• Suitable for production requirements of various quantity.

Grey & ductile iron casting:

- weight: 0.5-2000KG

- technology: Green sand, resin sand, vacuum casting, shell molding

- production line: DISA line, auto molding line, manual molding machine

- application: Pump, valve, automobile, agriculture, municipal, sports, metallurgy other mechanical field

Vacuum moulding line:

- available material: grey iron, ductile iron and alloy steel

- flask dimension: 1,000 mm × 800 mm × 500 mm

- weight scope: 0.5-100kgs

Resin Sand moulding line:

- available material: grey iron, ductile iron and steel

- flask dimension: 4200*4200*2000mm

- weight scope: 10-2000kgs

Moulding Autoline:

- available material: grey iron, ductile iron

- flask dimension:

- 508*609*250mm

- 350*450*150mm

- 400*500*180mm

-weight scope:0.2-50k

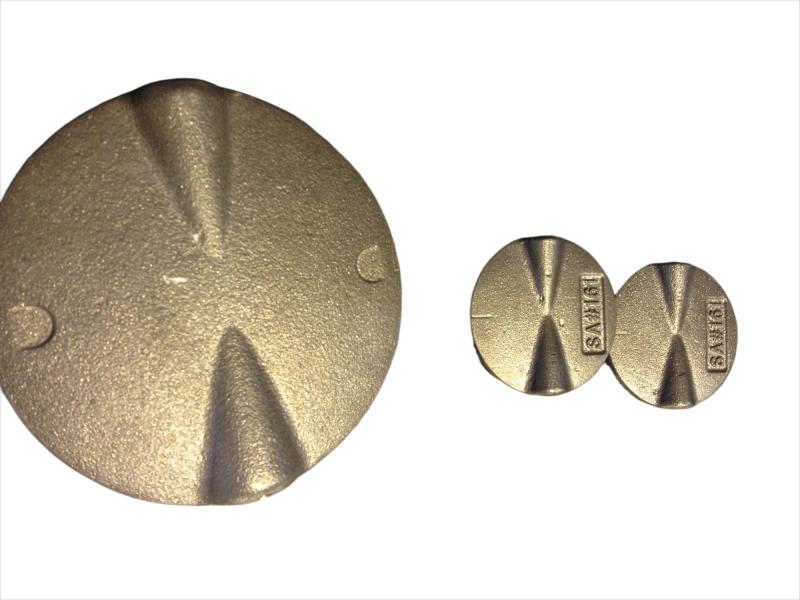

Product details

| Material |

Gray iron ,ductile iron, brass, carbon steel, copper, aluminum, alloy steel, etc |

| standard |

ASTM, ASME,DIN, EN, BS, JIS, ANSI, AS,GB etc. |

| process |

Green sand casting ,resin sand casting, shell molding casting,vacuum casting, continuous concast, machining |

| Weight range |

0.5-2,000kg |

| Surface treatment |

painting, polishing, heat treatment, annealing or galvanization etc. |

| Size and design |

As per the customer's drawings, samples and requirements |

| Machining |

complete machining such as CN machining,CNC lathe,CNC milling,drilling etc. |

| Packing |

As per customers' requirements |

| Inspection |

in-house or the third Party |

Packaging and Shipment

IPv6 network supported

IPv6 network supported