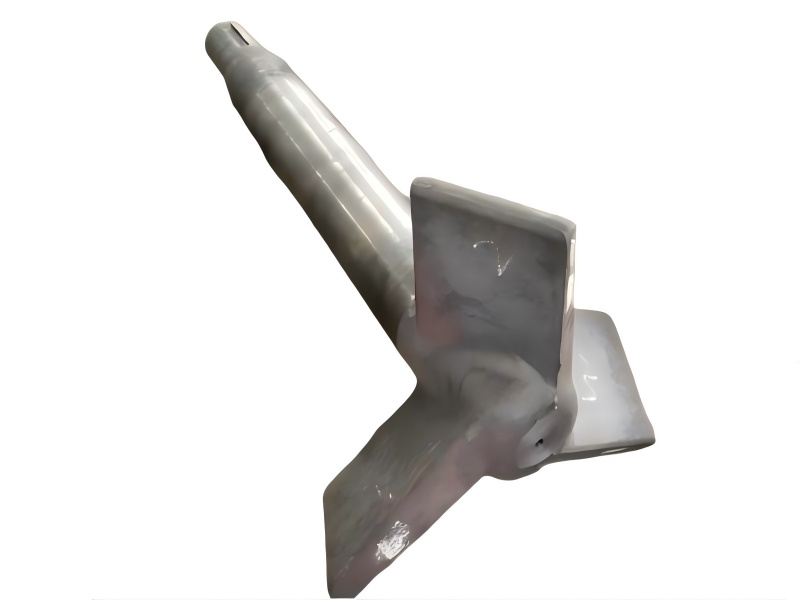

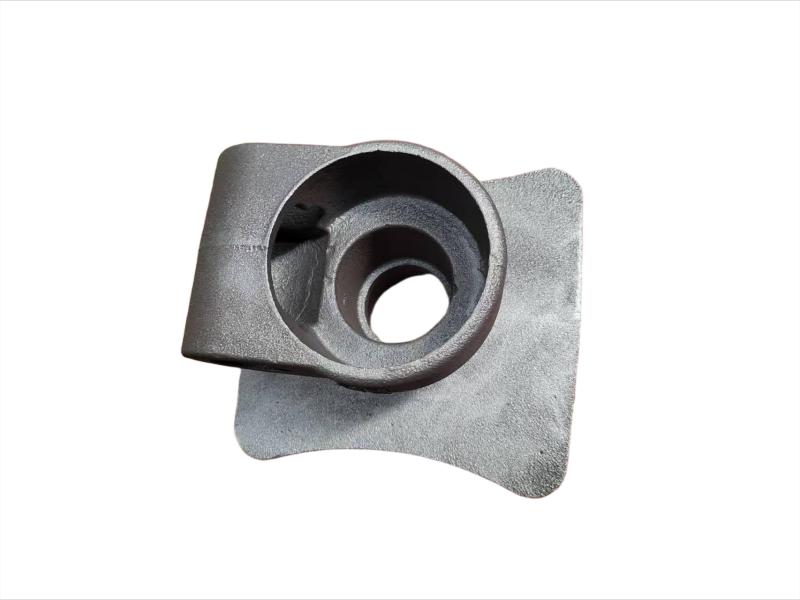

A ductile iron gate valve is a control valve that uses a sliding, disc-shaped gate made of ductile iron to start, stop, or regulate fluid flow in a pipe, offering excellent strength, durability, and corrosion resistance. These valves are ideal for high-pressure applications and widely used in industrial settings, water and gas distribution networks, and wastewater systems due to their ability to provide full flow or tight shut-off and long service life.

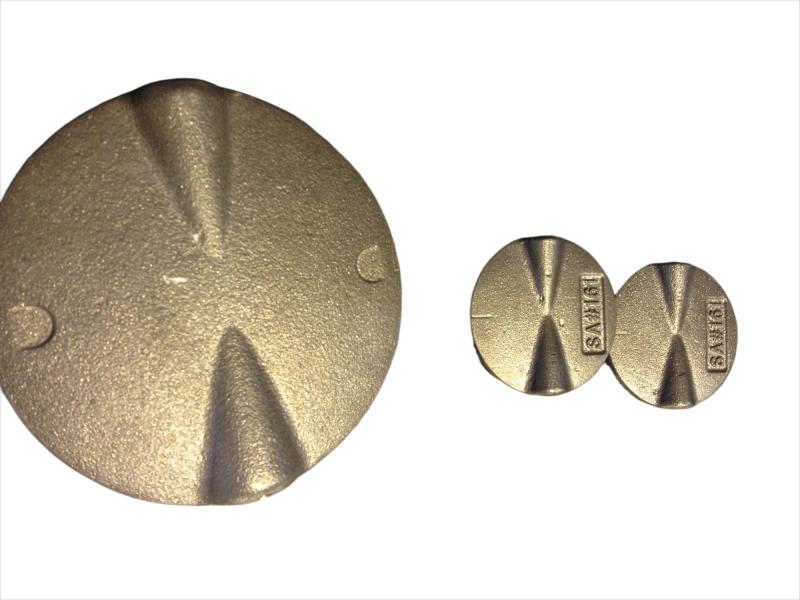

Hengchang is the leading producer of gray, ductile iron in China, melting more than 6000 tons per year, with more than 15 years experience. 65-45-12 valve housings are produced by resin sand casting process, which provides amazing benefits for manufacturers who are looking to make complex parts in smaller production runs using cost-effective methods. One of the main benefits is that resin sand casting creates a very smooth mold surface that is strong and solid. The reason is because of the sand’s collapsibility when the mold compresses while solidifying. So there are fewer casting defects as the molten metal can flow into every crevice of the mold to create accurate dimensions. Resin sand casting is ideal for very large castings that can weigh several tons. Yet this process is also ideal for smaller components that need customization. The process requires fewer workers to create the mold and production runs, which can also provide cost savings that can be passed on to the customer. Since the mold is very strong, it can make products for a wide range of applications, such as engine blocks, cylinder heads and other engine parts, hardware, electrical contact parts, pulleys, and even landing gear components.

| Production Line Capabilities |

1.Vacuum Casting Line: Enables large-batch production and smooth surface medium parts

2.Resin Sand Casting Line: Delivers big complex geometries, but small quantity

3.Clay Sand Casting Line: Enables large-batch production small part and smooth surface medium parts

4.Medium-frequency Induction Furnace: Make sure uniform melting and stable quality

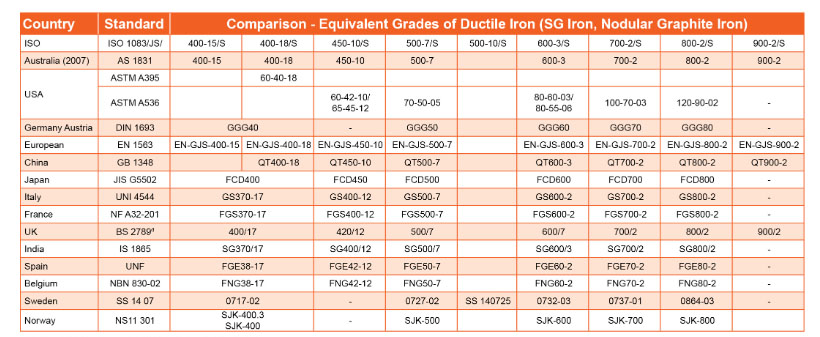

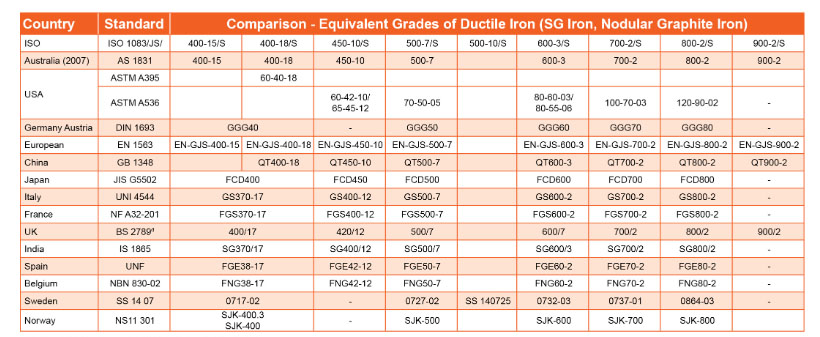

Comparison-Equivalent Grades of Ductile Iron

IPv6 network supported

IPv6 network supported