Bearing housing, also known as a bearing block or bearing pedestal, is a structural component that supports and protects a bearing. It provides a stable and secure environment for the bearing, ensuring proper alignment and performance. Bearing housings are crucial in various mechanical systems where rotational motion is involved, such as in machinery, automotive, and industrial equipment.

Hengchang is the leading producer of gray, ductile iron in China, melting more than 6000 tons per year, with more than 15 years experience. Our custom products widely use in different area, such as water pumps, valves, oil & gas, metallurgy, municipal, rail roads, sport, food service industry, automotive, agriculture machine, construction, etc. Welcome to visit Hengchang, the leading manufacturer in the foundry industry, and learn how our quality, consistency and service to support you win more market shares.

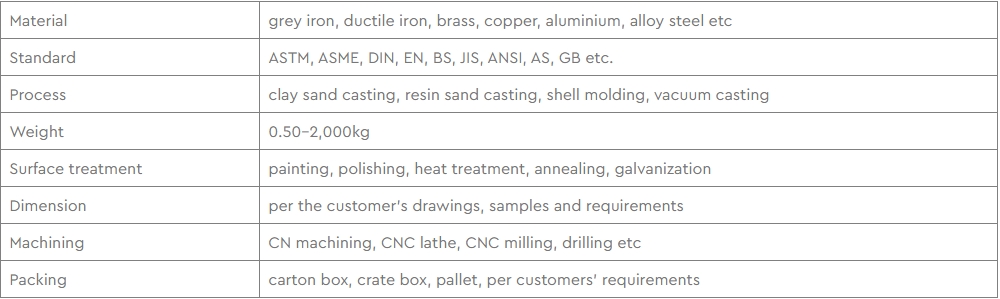

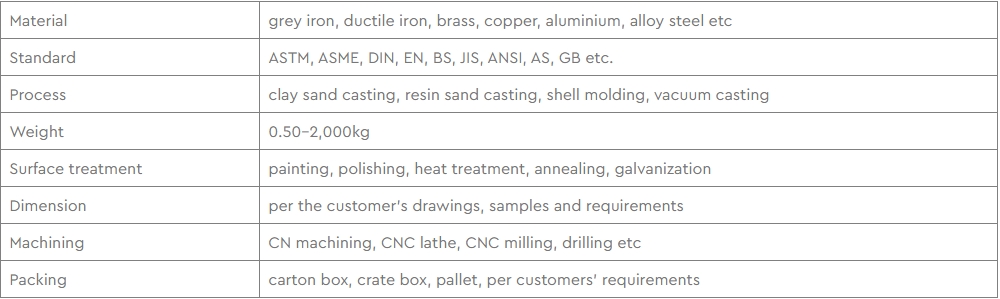

| Production Line Capabilities |

1.Vacuum Casting Line: Enables large-batch production and smooth surface medium parts

2.Resin Sand Casting Line: Delivers big complex geometries, but small quantity

3.Clay Sand Casting Line: Enables large-batch production small part and smooth surface medium parts

4.Medium-frequency Induction Furnace: Make sure uniform melting and stable quality

Comparative qualities of cast irons

| Name |

Nominal composition [% by weight] |

Form and condition |

Yield strength [ksi (0.2% offset)] |

Tensile strength [ksi] |

Elongation [%] |

Hardness [Brinell scale] |

Uses |

| Grey cast iron (ASTM A48) |

C 3.4, Si 1.8, Mn 0.5 |

Cast |

— |

50 |

0.5 |

260 |

Engine cylinder blocks, flywheels, gear box cases, machine-tool bases |

| White cast iron |

C 3.4, Si 0.7, Mn 0.6 |

Cast (as cast) |

— |

25 |

0 |

450 |

Bearing surfaces |

| Malleable iron (ASTM A47) |

C 2.5, Si 1.0, Mn 0.55 |

Cast (annealed) |

33 |

52 |

12 |

130 |

Axle bearings, track wheels, automotive crankshafts |

| Ductile or nodular iron |

C 3.4, P 0.1, Mn 0.4, Ni 1.0, Mg 0.06 |

Cast |

53 |

70 |

18 |

170 |

Gears, camshafts, crankshafts |

| Ductile or nodular iron (ASTM A339) |

— |

Cast (quench tempered) |

108 |

135 |

5 |

310 |

— |

| Ni-hard type 2 |

C 2.7, Si 0.6, Mn 0.5, Ni 4.5, Cr 2.0 |

Sand-cast |

— |

55 |

— |

550 |

High strength applications |

| Ni-resist type 2 |

C 3.0, Si 2.0, Mn 1.0, Ni 20.0, Cr 2.5 |

Cast |

— |

27 |

2 |

140 |

Resistance to heat and corrosion |

IPv6 network supported

IPv6 network supported