Aluminum alloy transmission Case is a jacket usually for the transmission of an automobile.

OEM & ODM automatic transmission case from Hengchang Foundry

Hengchang is the leading producer of aluminum alloy products in China, melting more than 6000 tons per year, with more than 15 years experience. We use sand casting process to produce the products. Sand casting, also known as sand molded casting, is a metal casting process characterized by using sand as the material. The term "sand casting" can also refer to an object produced via the sand casting process. Sand castings are produced in specialized factories called foundires. Over 60% of all metal castings are produced via sand casting process.

Molds made of sand are relatively cheap, and sufficiently refractory even for steel foundry use. In addition to the sand, a suitable bonding agent (usually clay) is mixed or occurs with the sand. The mixture is moistened, typically with water, but sometimes with other substances, to develop the strength and plasticity of the clay and to make the aggregate suitable for molding. The sand is typically contained in a system of frames or mold boxes known as a flask. The mold cavities and gate system are created by compacting the sand around models called patterns, by carving directly into the sand, or by 3D printing.

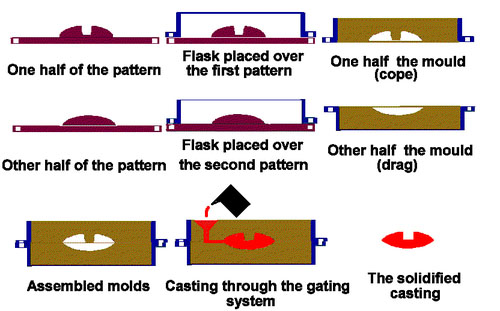

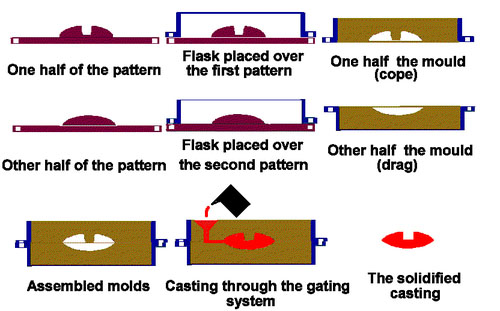

The Process of Sand Casting

1)Place a pattern in sand to create a mold.

2)Incorporate the pattern and sand in a gating system. Remove the pattern.

3)Fill the mold cavity with molten metal.

4)Allow the metal to cool.

5)Break away the sand mold and remove the casting.

Aluminum & aluminum alloy casting:

- weight: 50-100kg

- technology: vacuum casting, resin sand, shell molding

- application: Pump, valve, automobile, agriculture, municipal, sports, metallurgy other mechanical field

Our Advantages in Sand Casting Field:

• Over 15 years of experience in sand casting, shell molding casting and machining technology.

• Dimensionally accurate cores for complex internal contours.

• Strictly control the raw materials.

• Quality management throughout the production process and maximum process reliability.

IPv6 network supported

IPv6 network supported